-

Production of Ringlock Scaffolding Standard

1. Material selection: High-quality steel or aluminum alloy is chosen as the primary material for the standards. The material should have sufficient strength, durability, and resistance to corrosion. 2. Cutting and shaping: The selected material is cut into appropriate lengths according to the de...Read more -

How to install cuplock scaffolding?

To install cuplock scaffolding, follow these general steps: 1. Plan and prepare: Determine the layout and height of the scaffolding structure according to your project requirements. Ensure a stable and level ground for the base. Gather all the necessary components and tools for installation. 2. E...Read more -

Cuplock Scaffolding Standard

A Cuplock Scaffolding Standard is a vertical component used in Cuplock scaffolding systems. It is a cylindrical tube with built-in cups or nodes at regular intervals along its length. These cups allow for easy and quick connection of horizontal ledger beams, creating a rigid and stable scaffoldin...Read more -

The Role of Ringlock Scaffolding Base Collar

The base collar for ringlock scaffolding plays an important role in providing stability and support to the entire scaffolding structure. It is specifically designed to connect and secure vertical standards to the scaffolding base, ensuring a strong and secure foundation. The base collar acts as a...Read more -

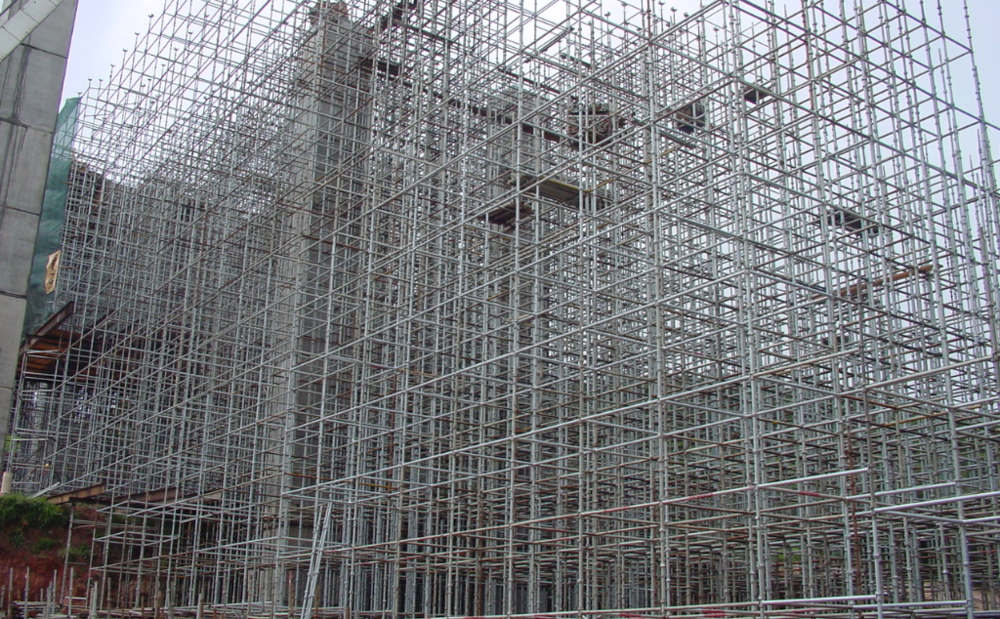

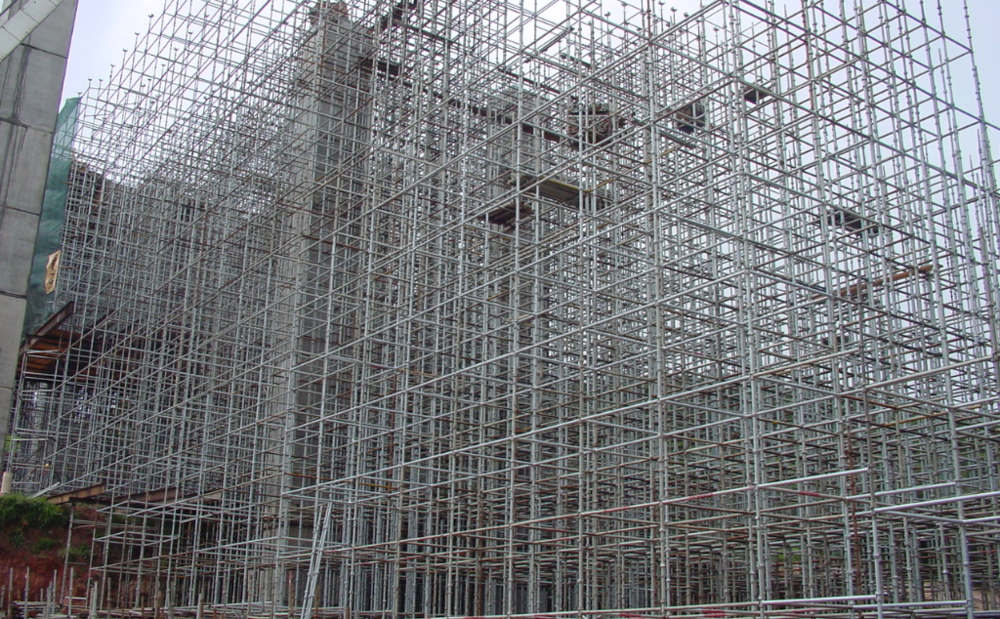

Notes on construction of coupler-type steel pipe scaffoldings

1. The spacing between poles is generally not greater than 2.0m, the horizontal distance between poles is not greater than 1.5m, the connecting wall parts are not less than three steps and three spans, the bottom layer of the scaffolding is covered with a layer of fixed scaffolding boards, and th...Read more -

How to prevent scaffolding collapse accidents

1. Special construction technical plans should be compiled for scaffolding used in multi-story and high-rise buildings; floor-standing steel pipe scaffolding, cantilevered scaffolding, portal scaffolding, hanging scaffolding, attached lifting scaffolding, and hanging baskets with a height of more...Read more -

Do you know what types of scaffolding there are

1. According to the construction materials Steel tube scaffolding, wooden scaffolding, and bamboo scaffolding. Among them, steel pipe scaffolding can be divided into disc buckle type scaffolding (the latest and safest scaffold at present), steel pipe fastening type, bowl buckle type, door type, e...Read more -

How to use kwikstage scaffolding safely

Kwikstage scaffolding is a type of modular scaffolding that can provide a suitable support structure for any domestic, industrial, mining or commercial project and can be flexibly transported and set up. Kwikstage scaffolding consists of multiple prefabricated or prefabricated components. Among t...Read more -

How many formwork props do we need

Formwork props are adjustable, high-strength formwork support tools that can support vertical loads during construction. In the process of dismantling the template structure, formwork props are also an indispensable tool. Next we will discuss how to determine the number of formwork props that nee...Read more