-

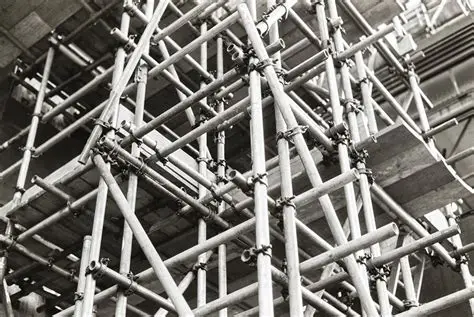

What are the installation methods for coupler-type scaffolding

The erection height of single-row scaffolding should not exceed 24m; the erection height of double-row scaffolding should not exceed 50m. For double-row scaffolding exceeding 50m in height, segmented erection measures should be adopted. The construction of longitudinal horizontal bars of scaffold...Read more -

What are the details that distinguish these different types of scaffolding

Bowl-lock Scaffolding: Bowl-lock scaffolding is a new type of socket-type steel pipe scaffolding. It features a unique toothed bowl-lock joint, offering rapid assembly and disassembly, labor-saving construction, stable and reliable structure, comprehensive equipment, strong versatility, high load...Read more -

How to maintain scaffolding for a longer lifespan

1. Establish and improve the system for the requisition, recycling, self-inspection, and maintenance of scaffolding materials and labor. Implement a quota-based acquisition or leasing system based on the principle of “whoever uses, maintains, and manages” for scaffolding tools, assign...Read more -

How to develop a comprehensive scaffolding erection plan

The development of a comprehensive scaffolding erection plan should follow these steps and precautions: 1. Working Conditions: The erection plan needs to be approved and thoroughly explained to the workers. All raw materials must be inspected; substandard materials are not permitted. Qualified ac...Read more -

What are the inspection items and standards for scaffolding

1. Standard Inspection for Ordinary Scaffolding: JG/T 503-2016. Inspection items: Compressive strength of adjustable base, compressive strength of adjustable support, shear strength of connecting plate on one side, shear strength of connecting plate on both sides, bending strength test of connect...Read more -

What are the installation methods for swivel couplers in scaffolding

The quality of the swivel coupler installation on scaffolding will affect its accuracy, lifespan, and performance. Therefore, please carefully study the installation methods for swivel couplers on scaffolding and follow the steps below. When installing swivel couplers on scaffolding, the installa...Read more -

What are the safety issues associated with scaffolding

First, the following potential hazards may exist with scaffolding: 1. Scaffolding construction plans were not prepared or approved promptly, and safety briefings were not signed off on by every worker. 2. Workers are working without licenses, without safety belts, helmets, or non-slip shoes; 3. S...Read more -

Are you still only scratching the surface when it comes to scaffolding acceptance

In procurement or project supervision, judging whether a set of scaffolding is “qualified” goes far beyond simply checking its new appearance. Its inherent material properties, structural logic, and detailed construction are the key factors determining the safety of the scaffolding. F...Read more -

What are the safety requirements for using disc-lock steel pipe scaffolding

First, the step distance of the scaffolding should not exceed 2m. Second, steel pipe couplers should not be used for the vertical diagonal braces of the scaffolding. Third, safety structural requirements for the scaffolding support frame: 1. The height-to-width ratio of the scaffolding support fr...Read more