A.Product Introduction

Disc scaffolding is a new type of scaffolding, which was introduced from Europe in 1980s, and is an upgraded product after the bowl buckle scaffolding. It is also called daisy disc scaffolding system, insert disc scaffolding system, wheel disc scaffolding system, buckle disc olding system, and rayon scaffolding, etc. The scaffold socket is a disc with 8 holes, 4 large and 4 small.

The crossbars are inserted at 90°perpendicular to the derivative frame into the small holes and the diagonal bars into the large holes. The cross bar can also be inserted into the large hole, and the angle can be adjusted within 15°. Widely used in: general viaduct and other bridge projects, tunnel projects, factory buildings, elevated water towers, power plants, oil refineries, etc. And special plant support design, also suitable for street bridges, span scaffolding, storage shelves, chimneys, water towers and indoor and outdoor decoration, large concert stage, background frame, stands, viewing stands, modeling frame, staircase system, sports competition stands and other projects.

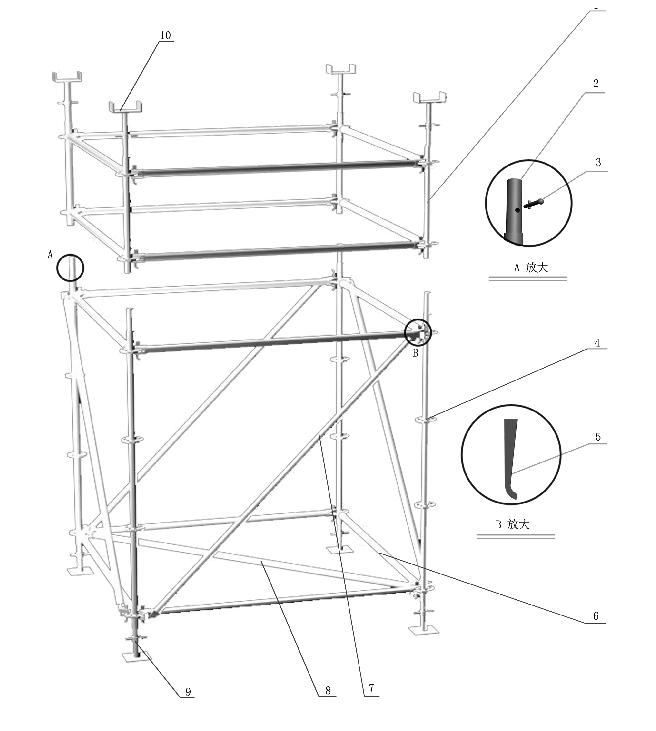

B. Product composition

It is mainly composed of uprights, horizontal rods, vertical inclined rods, horizontal inclined rods, adjustable bases and adjustable top brackets, etc.

1 – riser; 2 – riser connecting tube; 3 – riser connector; 4 – connecting plate; 5 – pin; 6 – crossbar. 7-Vertical inclined rod; 8-Horizontal inclined rod; 9-Adjustable base; 10-Adjustable top bracket

C. assembly method

Bite the crossbar plug into the disc of the upright, then insert the locking pin into the small hole of the disc and secure it with a hammer. To connec t the uprights, simply place one upright over the inner sleeve of the other upright. After installing the crossbar and upright, the locking pin of the tilt rod can be inserted into the large hole of the disc, making the crossbar and upright form a triangular structure to fix the whole system.

D. the system set up requirements

1.For interior wall support.

1). When the disc support system is erected formwork bracket, the erection height ≤ 24m; when it is greater than 24m, it should be designed and calculated separately.

2). When the disc support system is set up as formwork support, the size of the column should be calculated according to the construction plan and the horizontal rod of fixed length column, adjustable top bracket and adjustable base should be inserted according to the combination of support height.

3). When erecting the full hall formwork bracket of height ≤ 8m, the step distance ≤ 1.5m.

4). When erecting full hall formwork bracket with height ≥ 8m, the vertical diagonal bar should be set in full, the step distance of the horizontal bar ≤ 1.5m, and the horizontal layer diagonal bar should be set every 4-6 sections along the height, and should be reliably tied with the surrounding structure trip. For long independent high support mold frame, the ratio of the total height of the frame and the width of the frame H/B should not be more than 3.

5). The cantilever length of the adjustable top bracket of the formwork bracket upright rod extending the top horizontal rod ≤ 650mm, and the adjustable base inserted into the upright rod length ≥150mm; the horizontal rod step distance of the topmost layer of the shelf should be reduced by one disk buckle spacing than the standard step.

2.For exterior walls.

1). When using disc scaffolding to erect double-row external scaffolding, the height ≤ 24m, > 24m, must be additionally designed and calculated. Users can choose the geometric size of the scaffold according to the requirements of use, and the step distance of the cross bar of the phase collar should be 2m, the vertical distance of the vertical bar should be 1.5m or 1.8m, and should not be greater than 2.1m, and the cross distance of the vertical bar should be 0.9m or 1.2m.

2). Diagonal rod or scissor brace: one vertical diagonal rod should be set for every 5 spans per floor along the outside of the frame longitudinally.

3). Connecting wall members must be used to withstand the tensile and compressive loads of rigid rods, connecting wall members set two steps three spans.

4). Each step of the horizontal bar layer of double-row scaffolding, when there is no hooked tread or other hooked scaffold plate to strengthen the rigidity of the horizontal layer, should be every 5 span set horizontal inclined rod.

E. Packaging requirements

All types of products should be packaged according to the name and specifications of the classification bundle. Each package should be marked with the product name, specifications, quantity and other content of the label.

F. Transportation requirements

Do not mix with corrosive substances for transportation.

During transportation and loading and unloading, squeezing and throwing are strictly prohibited to prevent product deformation and damage.

G. Storage requirements

Products should be stored according to name specifications.

The product should be placed in a dry place to prevent media erosion and rain, snow, water immersion damage.

Post time: Apr-26-2022